Traditional Building Methods

Traditional building methods are the conventional way of constructing buildings on-site using materials and labor. However, traditional building methods have limitations and disadvantages. For instance, they are time-consuming, labor-intensive, and often require extensive coordination between different trades. Traditional building methods can lead to delays, cost overruns, and quality issues. They are also less sustainable and can generate waste and pollution.

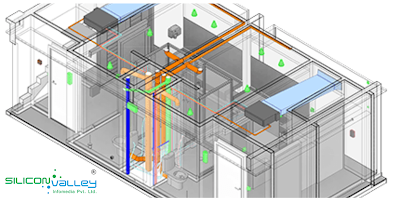

BIM in Building Design

BIM is a digital design tool that enables architects, engineers, and contractors to collaborate and communicate more efficiently during the design and construction process. BIM fabrication services allow digital models to be created, managed and shared. This helps to reduce errors, improve communication, and save time and money. With BIM, architects and engineers can simulate different building scenarios and test design ideas before construction begins. BIM can also help to reduce waste and increase sustainability by allowing for more accurate material estimates.

Prefabrication in Building Design

Prefabrication is a manufacturing process that involves building components in a factory and assembling them on-site. BIM for digital prefabrication services is an innovative approach that allows digital models to be created, analyzed, and optimized for prefabrication. Prefabricated building components can include walls, floors, roofs, and even entire buildings. Prefabrication can reduce construction time, labor costs, and waste. It can also improve quality control by allowing for more accurate manufacturing processes.

BIM and Prefabrication Working Together

BIM and prefabrication are complementary technologies that can work together to provide even greater benefits. By using BIM and digital fabrication design services, construction projects can be completed faster, more efficiently, and with fewer errors. BIM can be used to create detailed digital models of prefabricated components, allowing for more accurate manufacturing and assembly. BIM can also help to coordinate the installation of prefabricated components on-site, reducing errors and improving efficiency. BIM prefabrication means construction projects can be completed up to 50% faster than traditional building methods. Revit prefabrication services are a great example of how BIM and prefabrication can work together to deliver better buildings.

Case Studies

Many successful projects have been completed using BIM prefabrication services, demonstrating the benefits of these innovative approaches to building design. For instance, the modular construction of a hospital in Silicon Valley, California, using prefabricated building components manufactured offsite, was completed within just six months. BIM was used to create detailed digital models of the prefabricated components, allowing for more accurate manufacturing and assembly. The use of BIM and prefabrication reduced construction time by 30% and saved $5 million in construction costs compared to traditional building methods.

Future of Building Design

BIM prefabrication is transforming the construction industry, and it will continue to shape the future of building design. As technology advances, new innovations and technologies will emerge, allowing for even more efficient and sustainable building design and construction. For example, the use of drones and robots in construction could allow for more accurate site analysis and construction monitoring. The integration of augmented and virtual reality technologies could allow for more immersive design and visualization. BIM and prefabrication are just beginning a new era in building design and construction.

Conclusion

At Silicon Valley, BIM and prefabrication is the future of building design. Traditional building methods have limitations and disadvantages that can be overcome by using innovative digital fabrication services and BIM fabrication and prefabrication services. BIM and prefabrication working together can deliver faster, more efficient, and more sustainable construction projects. Successful case studies have demonstrated the benefits of using BIM prefabrication in construction, and the potential for new innovations and technologies is endless. As the construction industry continues to evolve, BIM and prefabrication will play a critical role in shaping the future of building design.

Comments

Post a Comment